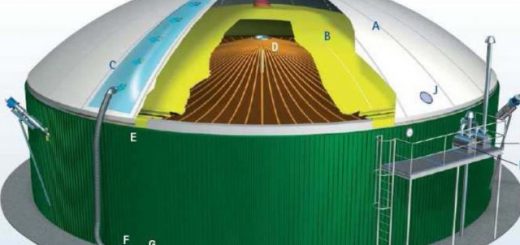

HDPE 100 PIPE BUTT WELDING APPLICATIONS

HDPE 100 PIPE BUTT WELDING APPLICATIONS

All 100 HDPE pipe butt welding and electro fusion welding your labor and you can call us for mechanical assembly …

office phone: +90 312 382 37 00

mobile phone: +90 532 283 01 62

pipe diameters up to 20 mm to 2000 mm

BUTT WELDING APPLICATIONS: Polyethylene (PE), PP and PVDF are the most economical and robust welding methods used for welding of fittings and fittings. Pipe is the kind of welding which is welded together by heating only its own material, no matter how many atmospheric compressive strength. This welding method is very economical because; sleeve, welding rod, etc. does not require anything. Once you get the forehead welding machine, you can combine the pipes with the pipes, the pipes, the fittings, and the fitings with heat dissipation.

Firstly, the pipes to be welded are connected to the side of the machine called the table and the settings are made.

the shaving unit which will correct the curvatures at the end points of the pipes is placed and all surfaces are smoothly shaved.

the shaving tool is removed and the forehead to be welded is cleaned so that the dust is free from dirt,

When the heater is placed in the heater together, the heating

By means of a pressure bonding process, the forehead welding is completed and the required cooling time is expected so that the welding process is done.

In the welding process, you do not need to use any additional cuffs or other materials in each welding place, so you have the opportunity to make the most economical way to make pipelines of many kilometers.

What is the difference between Butt Welding and Electrofusion Welding?

The most important difference between the Butt Weld and Electrofusion welding method is that you have to use additional parts of electrofusion cuffs or electrofusion fittings in each additional part in the electrofusion welding process.

However, in the field, you will encounter different situations such that the welding machine is not able to fit in place of the welding machine; Because the electro-fusion welding machine is given electrical current with the connection of the cables to the ef sleeve, welding process can be made more easily in narrow and difficult areas.

Akanlar Piping is taken from both machines as they are applied to any kind of welding application, where it is possible to get the job done more economically. The work is completed more quickly by using the electrofusion welding machine.

Butt-welding? or Electrofusion welding?

One of the most common questions we encounter is kaynak Butt Weld is better or better source of electrofusion? Olur and it is very good in both sources.

What should be paid attention to?

Good adjustment of the forehead of the pipes

Pipe trimming operation as required

To clean the surfaces to be welded with the appropriate substance in the best way

To make pressurized and free heating operation of heater with heater and conditions

To combine the technique with appropriate pressure and time

And as long as the required cooling time is adhered to, the bushing welding method is a truly robust and economical welding method preferred in the manually and visually controlled pressure pipes.

butt welding aplications on side area

Large diameter hdpe pipes and fittings (1600mm elbow)

(whatsapp)call for mobile phone +90 532 283 01 62

TELEFON:+90 312 382 37 00

FAX:+90 (312) 382 37 77

OFİS GSM: +90 542 382 37 00

GSM: +90 532 283 01 62

Mail: [email protected]

AKANLAR BORU ‘Polietilen Çözüm Merkezi’